A Complete Guide for Safer and More Efficient Aerial Operations

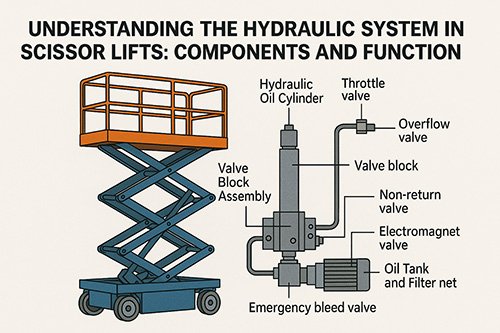

The hydraulic system is the heart of any scissor lift. It controls the lifting, lowering, and overall stability of the platform during operation. Whether you’re selecting a semi-electric model or a fully electric one, understanding how the hydraulic system works—and what components are involved—is critical for ensuring both safety and performance.

🔧 What Is a Hydraulic System in a Scissor Lift?

A hydraulic system uses fluid pressure to create mechanical movement. In a scissor lift, hydraulic oil is pumped into a cylinder, which pushes the scissor arms upward, lifting the platform. When the oil is released, the platform lowers in a controlled manner.

🧩 Key Components of the Hydraulic System

Here are the essential parts of the system and their roles:

1. Hydraulic Pump

Driven by an electric motor, the pump generates high-pressure oil flow that powers the lift. It’s the starting point of the lifting cycle.

2. Hydraulic Oil Cylinder

The core actuator. As pressurized oil enters the cylinder, it pushes the piston and raises the platform.

3. Valve Block Assembly

The central control unit for oil flow, which includes:

- Non-return Valve: Prevents backflow of oil, ensuring steady lifting.

- Overflow Valve: Controls maximum pressure to avoid overload.

- Electromagnetic Valve: Manages oil flow direction during lifting and lowering.

4. Throttle Valve

Adjusts the oil flow rate to regulate the speed of descent, providing a smooth and stable drop.

5. Oil Tank and Filter Net

Stores the hydraulic oil and removes impurities. Keeping this clean is essential for system health.

6. Emergency Bleed Valve

Allows safe descent in case of power failure or system error.

⚙️ How the Hydraulic System Works (Step by Step)

- Lifting Phase

The electric motor activates the pump → hydraulic oil is pushed into the cylinder → the piston extends → platform rises. - Holding Phase

The non-return valve closes → oil remains trapped in the cylinder → the platform stays at height without drifting. - Lowering Phase

The electromagnetic valve opens → oil flows back to the tank via throttle valve → platform descends slowly under gravity.

✅ Benefits of a Well-Designed Hydraulic System

- Smooth Elevation and Descent

Load changes won’t affect speed thanks to pressure-balancing design. - Enhanced Safety

Overflow and emergency valves prevent overpressure and uncontrolled drops. - Durability

High-quality components reduce maintenance frequency and cost.

🛠️ Maintenance Tips

- Replace hydraulic oil every 6 months or based on pollution level.

- Never mix oil types or let water enter the system.

- Clean the valve block regularly to avoid clogging.

- Check for leaks, damaged seals, or stuck valves periodically.

Final Advice

When evaluating a scissor lift, always ask about the hydraulic system design, safety features, and replacement part availability. A stable, efficient hydraulic system means safer work at height and longer machine life.